Introduction

The role that Carbon Capture Utilisation and Storage (CCUS) will play in achieving a global net-zero will be pivotal. Whilst the world strives hard to decarbonise heavy industry, transport, electricity and heating, there will always be a proportion of unabated emissions. It is, therefore, carbon removals in the form of natural carbon sinks, carbon capture and methane splitting that will help us counterbalance all remaining emissions to achieve a true net-zero. When combined with bioenergy technologies for power generation (so-called BECCS – bioenergy with carbon capture and storage), CCS has the potential to generate ‘negative emissions’, removing CO2 from the atmosphere. Understandably, many policymakers believe that this will be an essential technology to help reach the goals of the Paris Agreement; hence, the Global CCS Institute estimates that 2,500 facilities will be required globally by 2040.

How does carbon capture work?

Carbon capture is the process of capturing carbon dioxide (CO2) before it is released into the atmosphere. It is estimated that the technology can capture up to 90% of flue gases released by burning fossil fuels in electricity generation and industrial processes. Methods used in the capture process include absorption, adsorption, chemical looping and oxyfuel combustion. These processes are required to separate the CO2 from the flue gas.

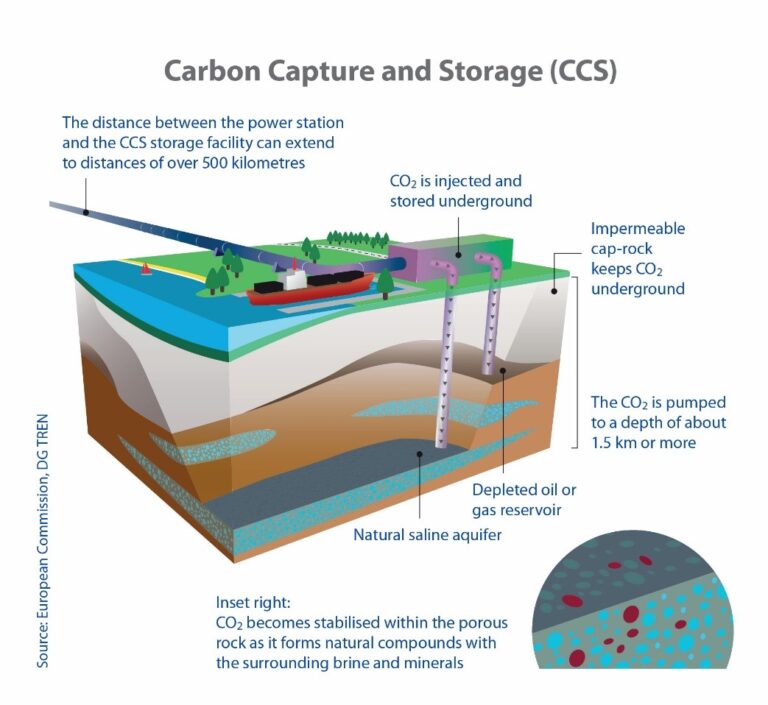

After capture, the CO2 must be compressed to liquid form and transported to suitable storage sites. Pipelines are the cheapest forms of transport, ships can be used where pipelines aren’t feasible, however, transport by rail or tanker can cost twice as much.

Sequestration of the CO2 must be done at a location where the geology is suitable to mitigate the risk of carbon leakage. Usually, the CO2 will be pumped deep underground (to depths of 1.5km or more) to be stored in depleted oil and gas reservoirs, coal beds and saline formations (see figure below).

The utilisation aspect of CCUS comes from using the CO2 to produce a commercially marketable product. The most well-established form of CO2 utilisation is enhanced oil recovery, where the CO2 is injected into oil and gas reserves to increase their extraction. However, because CO2 is released when the oil is burned, the process itself is not carbon neutral.

What are the drawbacks?

Cost is the most significant barrier to investment in CCS technology. For a project to be feasible, the cost of CCS, plus any subsidies, must be less than the perceived cost of emitting CO2. The capture stage is deemed the most cost-heavy step of the process. High deployment costs and energy costs associated with compressing and extracting the CO2 add significant operational costs to the system that can only be combatted through the use of cheap, renewable energy. If a CCS plant is supplied by energy from fossil fuel sources, then inherently, the system is much less efficient in reducing CO2 emissions. This means that the cost of CO2 captured would actually be lower than the cost of CO2 avoided.

The cost of CCS varies significantly between processes: where CO2 is already produced separately in concentrated streams, for example in fertiliser production, the cost is lower, but for processes that don’t do this, such as cement production and power generation, the cost is much higher.

Example Projects:

United Kingdom

In the UK CCS is under consideration to help with industry and heating decarbonization. Previously, the 2020 budget allocated 800 million pounds to attempt to create CCS clusters by 2030, to capture CO2 from heavy industry and a gas-fired power station and store it under depleted gas stores in the North Sea.

Since then, and outlined in the new net-zero strategy, the UK has set up the Industrial Decarbonisation and Hydrogen Revenue Support (IDHRS) scheme, providing up to £140 million to fund new hydrogen and industrial carbon capture business models. Further to this, a £19.5 million grant in funding is available to support novel CCUS technologies that will help reduce the cost of deployment and the first locations of carbon capture clusters in the industrial heartlands are currently being decided on. The Crown Estate is responsible for storage rights on the UK continental shelf and is facilitating work on offshore CO2 storage technical and commercial issues.

In 2018 a pilot project of bioenergy with carbon capture and storage (BECCS) was trialled at the Drax biomass powerplant in Selby. By early 2019, the project was operational and had captured the first trace of carbon. A second pilot project installed at the same plant by Mitsubishi Heavy Industries (MHI) in Autumn 2020 enhanced Drax’s technical understanding of BECCS. This second successful trial led to the two companies to agree on a long-term contract for Drax to use MHI’s carbon capture technology.

As of 21st October 2021, Drax has announced that it is undergoing major planning consultation to seek the views of the public on developing fully operational BECCS infrastructure at its plant in North Yorkshire. The announcement comes after the government reported that the East Coast Cluster, a collaboration between Net Zero Humber and Net Zero Teeside, is a priority CCUS location. Construction is expected to begin in 2024, with the system to be operational by 2027.

Figure 2: Biomass domes at Drax power station Selby, England

United Arab Emirates

After the success of their pilot project in 2011, the Abu Dhabi National Oil Company and Abu Dhabi Future Energy Company moved to create the first commercial CCS facility for the iron and steel industry. The CO2 generated from the production of steel is captured and transported via a 50km pipeline to oil reserves owned by the Abu Dhabi National Oil Company to help with enhanced oil recovery. The CCS facility has the capacity to capture up to 800,000 tonnes of CO2 a year.

Summary

As a technology, CCUS will be critical for putting energy systems around the world on a sustainable path. Despite its importance, uptake for the technology has been slow – there are only around 20 commercial CCUS operations worldwide. A number of factors have caused this, with high CAPEX and OPEX costs being the most cited. CCUS is unable to compete with wind and solar electricity given their spectacular fall in costs over the last decade, while climate policies (e.g., emissions trading and carbon pricing) are not yet strong enough to make CCUS economically attractive. It is predicted that the cost of carbon allowances in the EU Emissions Trading Scheme would have to reach around 100 EUR/ tonne CO2 to make a CCUS project financially feasible. That being said, to dismiss the technology on cost grounds would be to ignore its unique strengths, its competitiveness in key sectors and its potential to enter the mainstream of low-carbon solutions. Many still believe that achieving net-zero goals will be virtually impossible without CCUS and BECCS.